Humans are funny. We often make decisions that we believe are for one reason, only to learn we may have subconsciously made that choice for another reason. For example, did you know it has been proven through research studies that people like others with the same first name more than people with different names upon meeting them? As a middle schooler, my two best friends were also Lisa. How predictable am I?

Whether you agree with this particular research or not, most people do like to be around or take advice from people who are like them or have similar interests. So I took this cue when developing today's blog. Instead of hearing from me, I wanted you to hear from business owners like yourself. I wanted to share the real reasons why business owners buy cardboard balers and trash compactors. And just in case there was a chance of any name biases when it came to Orwak equipment, I did not accept input from anyone named Oliver, Olivia or Oscar. :)

The Top 5 Reasons Why Business Owners Buy Cardboard Balers & Trash Compactors

#1 We want our employees spending more time inside with customers, not dealing with the trash outside of the building.

According to Steve, “In addition to the cost savings, our employees spend more time serving customers. During our busiest times, our employees can compact waste instead of carrying it outside. We estimate that on each shift, we’ve gained back 40 minutes of time that our team would have spent moving trash and cardboard outside. It has also led to a safer work environment for our night shift employees.”

#2 The trash in our dining area was piling up faster than we could get rid of it.

Steve Dolio of SuperSandwich needed a solution that could handle a lot of garbage in a short period of time. Each day SuperSandwich serves approximately 300 to 400 guests during the narrow 11am to 2pm lunch window. Since his team was focused on serving customers, the trash piled up fast. Before TOM, the store had two traditional garbage cans that had to be emptied constantly.

“It was a mess and waste piled up on the floor, but with TOM in operation we went from 8-10 full bags a day to just 1 per day," according to Steve. "Most of the time, the one TOM bag still had more room for trash, but we changed it anyway for hygienic reasons.”

#3 Customers have high expectations of what they expect to see (and not see).

According to Henry Rzemieniewski, MetLife Stadium’s Cleaning Operations Manager, patrons of the $1.6 billion MetLife Stadium – particularly NFL season ticket holders – have high expectations for their stadium experience. “They expect it to be functioning in a clean and sustainable way with efficient trash management and recycling,”

Before investing in Orwak, Rzemieniewski had large crews ready to “pick the bowl,” empty trash and recycling bins, and comb the parking lot for trash. This labor-intensive process had two key challenges:

- Cleaning crews were not always working to full capacity

- The sheer volume of the trash made local storage points impractical

“The strategic placement of the balers has created a huge productivity increase for our cleanup crews,” says Rzemieniewski. “As we roll out our improved waste handling systems and processes, we expect to see significant savings in labor costs alone. Since we are also meeting our objective of maintaining a clean, welcoming environment for fans, our investment in Orwak equipment has resulted in a win for everyone."

#4 We wanted a user friendly solution that was easy for management to implement and easy for staff to use.

“The Orwak 3110 Compact caught our eye because of its compact size. It could fit in a little nook,” stated Jack Moore, Facilities Director at Roots Market. “It also uses 110-volt current and produces bales of 80 to 100 pounds, which are easier to maneuver.”

We know that as a business owner, trash wasn't something you looked forward to dealing with when you opened your business. We also know that these aren't the kind of purchases people like to do often. The good news is, with Orwak you don't have to.

Orwak balers and compactors are designed using material-optimized construction, laser cutting and advanced bending technology and Black Star Technology, a new proprietary hydraulic technique that provides increased strength and durability. In addition, every Orwak machine is built using the highest quality standards in the industry:

- ISO 9001 - Quality Management

- ISO 14001 - Environmental Management

- ISO 3834 - Welding for heavy steel construction products

But owners know that the key to longevity of Orwak compactors and balers are the inexpesive parts that keep them running long past their expected life. Case in point - Minnesuing Acres, a beautiful Executive Retreat and Conference Center located directly on the picturesque Lake Nebagamon in Wisconsin, has used their Orwak 5030 on a continuous basis, with zero safety issues and only minor maintenance and part replacements, for over 29 years! Talk about return on investment!

According to Jon Lindberg, Caretaker at Minnesuing Acres, “The Orwak 5030 makes managing trash much simpler. It paid for itself, a long, long time ago. We would buy a new one, but the old one just keeps on going and going and going!”

When asked about his overall impression of the Orwak 5030, Jon stated, “I wish everything was built like an Orwak 5030!”

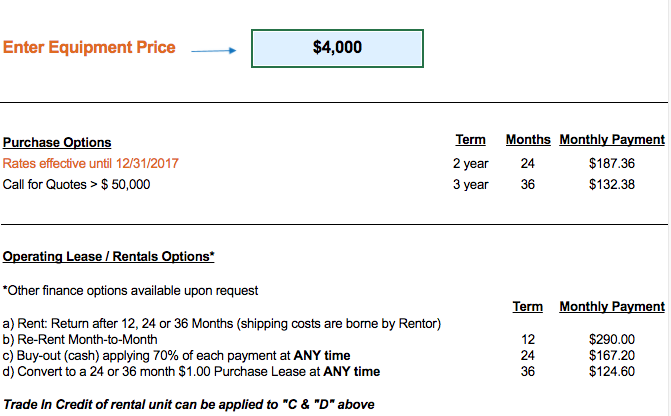

An Orwak compactor or baler is one of the few investments that can pay for itself and potentially create income over time. Orwak North America offers a multitude of purchasing options to make owning an Orwak compactor and/or baler affordable to businesses of all sizes.

The four most popular ways to get started with an Orwak compactor or baler is:

- Buy (direct purchase)

- Rent

- Lease

- Lease-to-Own

Let Us Know What You Thought about this Post.

Put your Comment Below.